DuraBeam®︎

This product was developed by TamaBio Co., Ltd. using patented medical sheet technology in Japan, the United States, the People’s Republic of China, and Taiwan, and has received regulatory approval.

- Product Name

-

DuraBeam®︎

- Approval number

-

22900BZX00291000

- Device

Common Name -

synthetic artificial dura mater

- JMDN code

-

70511000

- Sterilized

-

single use

- Product number

Product Sizes

Product Sizes - D-300-1212

LL size

12cm×12cm

thickness 300μmJAN Code4589795950135

D-300-1010L size

10cm×10cm

thickness 300μmJAN Code4589795950128

D-300-1005M size

10cm×5cm

thickness 300μmJAN Code4589795950111

D-300-0505S size

5cm×5cm

thickness 300μmJAN Code4589795950104

| Product number | D-300-1212 | D-300-1010 | D-300-1005 | D-300-0505 |

|---|---|---|---|---|

| Product Sizes | LL size | L size | M size | S size |

| JAN Code | 4589795950135 | 4589795950128 | 4589795950111 | 4589795950104 |

*This product uses a patent from RIKEN a National Research and Development Institute.

Manufacturer: TamaBio Company Limited

402 Gran Creste 2-2-18 Sakai Musashino-shi Tokyo 180-0022 Japan

TEL : +81-422-53-5051

FAX : +81-422-38-5091

1.Product overview

[Product Name] DuraBeam®︎

[Category] Medical supplies 04 Orthopedic supplies

[Device Common Name] Synthetic artificial dura mater

[Class classification] IV

[Date of approval] September 1, 2017

[Approval number] 22900BZX00291000

[Purpose of use or effect] Brain dura mater replacement and substitution

[Structure/Principle]

This product is a sheet made of expanded polytetrafluoroethylene (ePTFE), and one side is irradiated with an ion beam.

The ion beam irradiated surface has a slightly brown color, and the non-irradiated surface is white and smooth, so it is possible to distinguish between the irradiated and non-irradiated surfaces.

For distinction, “Ion”mark is stamped on the irradiation surface. The thickness is 300μm.

Development history / Development concept

・As an artificial dura mater, it reduces the incidence of cerebrospinal fluid leakage through good adhesion and regeneration of living dura mater.

As a bioprosthetic material, ePTFE is a material that is extremely stable and does not deteriorate in the body, but due to the poor adhesiveness of fibrin glue and poor biocompatibility with surrounding tissues, it has been pointed out that adverse events such as cerebrospinal fluid leaks from small gaps between ePTFE and dura mater or in needle holes due to sutures occur.

RIKEN a National Research and Development Institute, Tokyo Women’s Medical University, and the Institute of Chemistry and Serum Therapy conducted research into preventing postoperative cerebrospinal fluid leakage by surface modification through ion beam irradiation (roughening the ePTFE surface to improve cell adhesion).

Four types of monovalent positive ions (4He+, 20Ne+, 40Ar+, 84Kr+) were irradiated onto ePTFE, and a comparative study of biocompatibility was performed on the dura mater. In order to analyze the adhesion and sealing effect between the ion beam irradiated ePTFE and the dura mater, a test of embedding samples into rabbit dural defects was performed. As a result ion irradiated samples were firmly attached to the dura mater and skull of the living body immediately after fibrin glue was applied. Furthermore, in a 1-month indwelling test of a sample in a rabbit dural defect, no cerebrospinal fluid leakage was observed with ion beam irradiated ePTFE compared to non-irradiated ePTFE.

Samples prepared under the optimal ion beam irradiation conditions (ion species, acceleration energy, irradiation dose per cm²) were sent to the Department of Neurosurgery, Tokyo Women’s Medical University, after approval by the university’s medical ethics committee. When used in 20 cases with cerebrospinal fluid leak during nasal pituitary tumor removal, one patient had recurrence of cerebrospinal fluid leak, but postoperative cerebrospinal fluid leak could be prevented in 19 patients.

(Cited document: Journal of the Japanese Endocrine Society Vol.80 Sep. 2004)

・Ease of re-extraction

As mentioned above, this product adhered to living tissue and improved the prevention of cerebrospinal fluid leakage, but no adhesion to tissue could be confirmed, suggesting that it could be easily removed by re-cranial surgery.

・Soft fit to the body

Manufactured using a unique molding method using multi-axial stretching, it has an outstanding feel and softness.

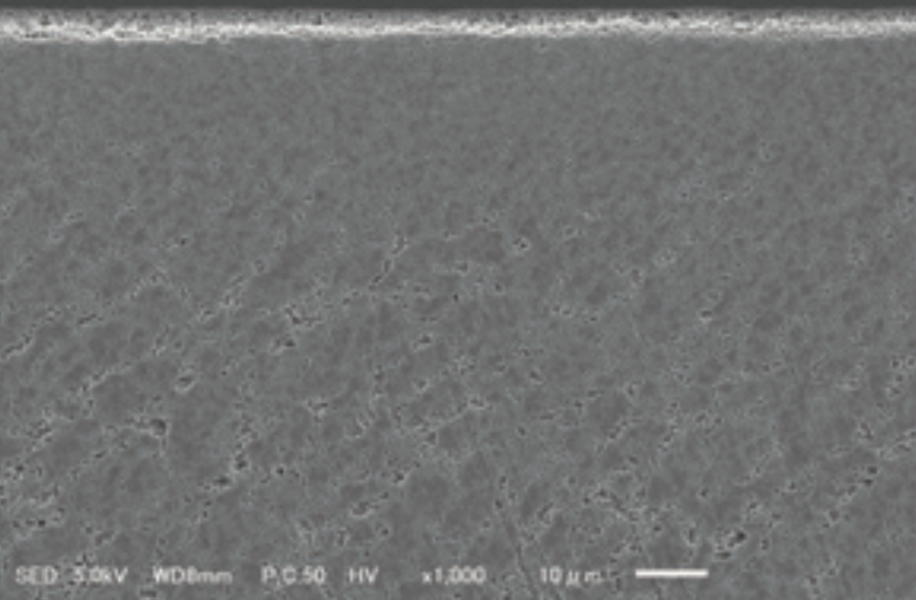

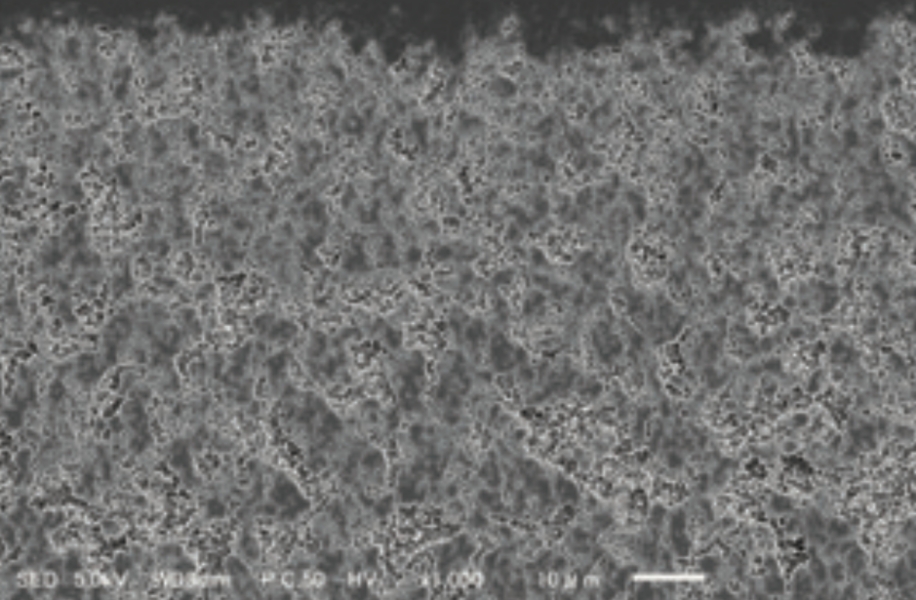

Cross-sectional electron micrograph (×1000)

- Ion beam irradiation causes unevenness on the irradiated surface.

- Etching processing by sputtering

Dog dural implantation test

[Implantation method] Implantation between the dura mater and brain parenchyma

[Group 1 (control/similar medical device)] Both the inner and outer surfaces are smooth.

[Group 2 (DuraBeam®/forward direction)] Implanted with the ion beam irradiated surface facing outside (skull side) and the smooth surface facing inside (brain and spinal cord side)

[Group 3(DuraBeam®︎/reverse direction)] Implanted with the ion beam irradiated surface facing inside(brain and spinal cord side)and the smooth surface facing outside(skull side)

[Observation period] 30 days

[Test results] No cerebrospinal fluid leakage, malfunctions, or adverse events were observed in all cases.

[Histological examination] Representative photographs are shown below.

No adhesion to tissue was observed on the control product and the non-ion beam irradiated surface. The ion beam irradiated surface is found to be compatible with the tissue.

Dog dural implantation test: 30 days later

control group

Animal No. M01103

DuraBeam®︎/forward direction

Animal No. M02204

Dog dural implantation test: 30 days later

control group

Animal No. M01103

DuraBeam®︎/reverse direction

Animal No. M03303